Materials for Extremes

Meeting the challenge: advancing alloys, ceramics, and their composites for technologies deployed in the world’s harshest conditions

From the chemically corrosive environments experienced by sea-going vessels, medical implants, and nuclear reactors to the high-temperatures and mechanical shock exposures affecting hypersonic flight vehicles, materials developed to operate in extreme conditions have far-reaching implications for the economy, national security, and human health. Our researchers work across traditional metallic and ceramic material systems to uncover and advance how extreme environments impact the function of materials and how those extremes can be leveraged to form novel or enhanced performance materials.

UT’s Approach

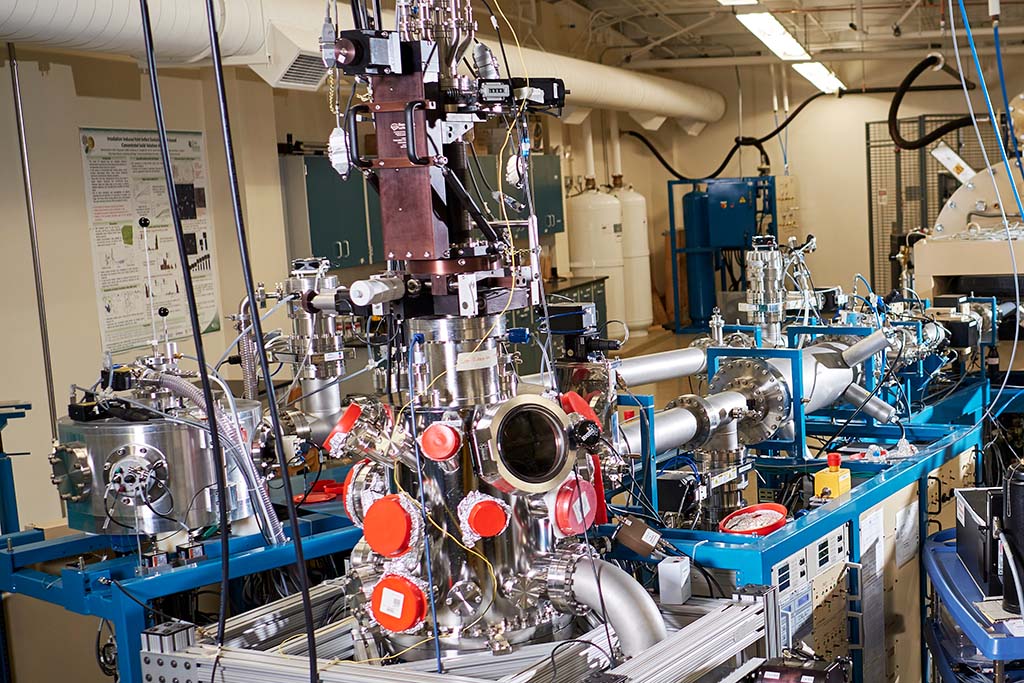

Our researchers combine high-throughput computational and experimental techniques with state-of-the-art ion irradiation, neutron scattering, and multi-scale materials modeling capabilities to interactively design, synthesize, and test next-generation materials intended for operation in extreme conditions, tackling problems far outside of what is considered the norm.

By examining the paradigms of hierarchical microstructure and compositional complexity, we explore strategies to enhance material performance and survivability. We collaborate broadly to advance and apply state-of-the-art neutron, electron, and theoretical probes at UT and Oak Ridge National Laboratory to study and advance material behaviors under ion irradiation/high temperature/high pressure exposures, high mechanical strain rates, and more.

Our distinguished faculty and high-profile research platform attract a diverse group of students expertly trained in the materials for extremes design cycle and prepared to meet the material challenges of tomorrow. UT is actively recruiting undergraduates, graduate students and postdoctoral fellows to work in this exciting area.

Highlights

Hypersonics at UTSI

The UT Space Institute in Tullahoma is at the forefront of hypersonic flight research and is leading a multi-university team to develop the essential educational curricula for the future hypersonic workforce.

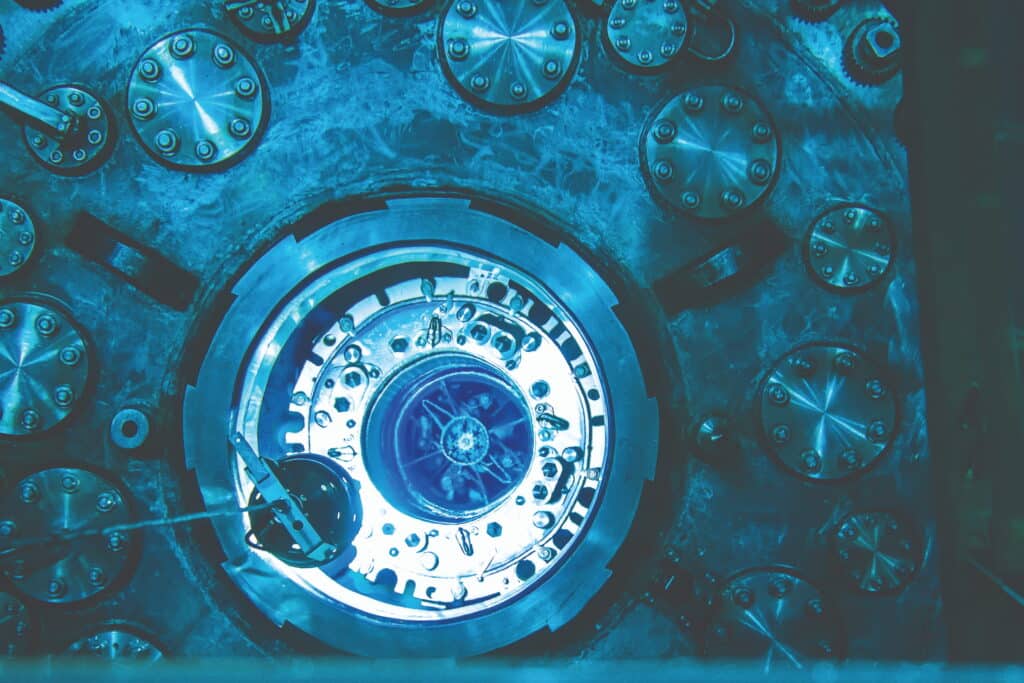

Radiation-Resistant Materials

A group of UT and ORNL researchers have developed a breakthrough material using high-entropy alloys, which uses different combinations of elements to fine-tune chemical complexity at the level of both electrons and atoms, and produces alloys more tolerant to radiation, giving them a longer life in terms of their use in nuclear power production.

Talent

-

Associate Professor, Mechanical, Aerospace & Biomedical Engineering

Developing new high-performance materials for additive manufacturing technologies, printable fiber-reinforced polymer and ceramic matrix composites, multi-material hybrid structures

-

Professor, Materials Science & Engineering

Analytical and computational mechanics of materials, small scale mechanical behavior, failure of advanced structural materials, thin film heterostructures

-

Chancellor’s Professor & Department Head, Materials Science & Engineering

Elastic constants and lattice dynamics of novel materials, including transition metal oxides, frustrated magnets and spin glasses, thermoelectric materials

-

Associate Professor, Nuclear Engineering

Radiation damage and high-pressure studies, materials science

-

Assistant Professor, Materials Science & Engineering

Phase transformations and microstructural evolution in metals and alloys, thermodynamic and kinetics, high-temperature materials, additive manufacturing

-

Professor, Materials Science & Engineering

Mechanical behavior, fatigue and fracture behavior, nondestructive-evaluation, and neutron/synchrotron studies of advanced materials, including bulk-metallic glasses, nano-structural materials, high-entropy alloys, superalloys, steels, and intermetallics.

-

Research Professor, Materials Science, Nuclear Engineering

Scintillation materials for next-generation gamma-ray, x-ray, and neutron detectors; characterization of new luminescent materials via optical and x-ray spectroscopy, implementation of emerging scintillator technology in medical imaging systems, homeland security inspection systems, neutron and particle physics experiments, and remote sensing; single crystal growth and powder synthesis of novel scintillation materials

-

Assistant Professor, Materials Science & Engineering

New insights into complex functional materials, both bulk and nano, through advances in structural characterization, ferroelectric oxides, energy conversion materials, nanoscale catalysts

-

Peebles Professor, IAMM Chair of Excellence, Civil & Environmental Engineering

Carbon fiber reinforced polymeric composites and sandwich structures, environmental degradation, and multi-scale mechanics, multi-axial stress-strain-time behavior of multi-phase and granular materials, non-invasive characterization and residual stress using neutron and x-ray tomography and diffraction, direct numerical simulations and porous media

-

Professor, Materials Science & Engineering

Quantum materials synthesis, molecular quantum systems, 2D materials, quantum magnetism, strongly correlated electron systems, nanoscale electron, ion and photon beam induced processing, thin film processing and characterization

-

Professor, Materials Science & Engineering

Materials engineering, macromolecular and materials chemistry, atomic/molecular physics, inorganic chemistry, neutron and X-Ray powder diffraction, small molecule crystallography, ceramic synthesis, structure/property relations

-

Associate Professor, Civil & Environmental Engineering

Computational mechanics, interface mechanics, composite material modeling, stabilized methods, high-performance computing

-

Associate Professor, Materials Science & Engineering

Computational materials science, density functional theory and atomistic simulations, defect interaction and radiation effects, deformation mechanism and electronic/magnetic effects on mechanical properties of structural alloys, electromagnetic coupling and flexoelectric effects, materials for neuromorphic computing, mesoscale computational methods

-

Associate Professor, Materials Science & Engineering

Discovery, synthesis and characterization of scintillators for homeland security and medical imaging applications

-

UT-ORNL Governor’s Chair for Nuclear Materials

Physical metallurgy of structural materials; ion and neutron irradiation effects on the microstructure, physical and mechanical properties of metals and ceramics; fusion and fission reactor materials; deformation and fracture mechanisms.