Advanced Manufacturing

At the forefront of maintaining American technological superiority in advanced manufacturing

Drawing on world-renowned talent, our faculty members incorporate expertise in hybrid, solid state and composites manufacturing, advanced metrology, and machine tools to diagnose and solve some of the most complex challenges for industry and government.

These efforts dovetail with our world-leading research in global supply chain, energy policy, environmental policy, global security, leadership and governance, and artificial intelligence.

UT’s Approach

Advanced manufacturing research at UT is uniquely conducted in partnership with public, private, community, and industry partners to promote economic development, enhance national security, share knowledge, and engage a skilled and trained manufacturing workforce.

Through online and in-person programs, UT is directly addressing workforce development needs within the defense, aerospace, automotive, medical, consumer goods, and energy production industries.

Working collaboratively with external partners, our faculty and students conduct groundbreaking research in large area additive manufacturing for composites; metal additive manufacturing using powder bed processing, wire arc, and additive friction stir deposition techniques; convergent manufacturing of multi-material systems, hybrid automated manufacturing for industry 5.0; and contemporary design practices for additively-manufactured architecture.

Highlights

UT Art and Engineering Partner to Address Pressing Work Shortage in National Defense Manufacturing

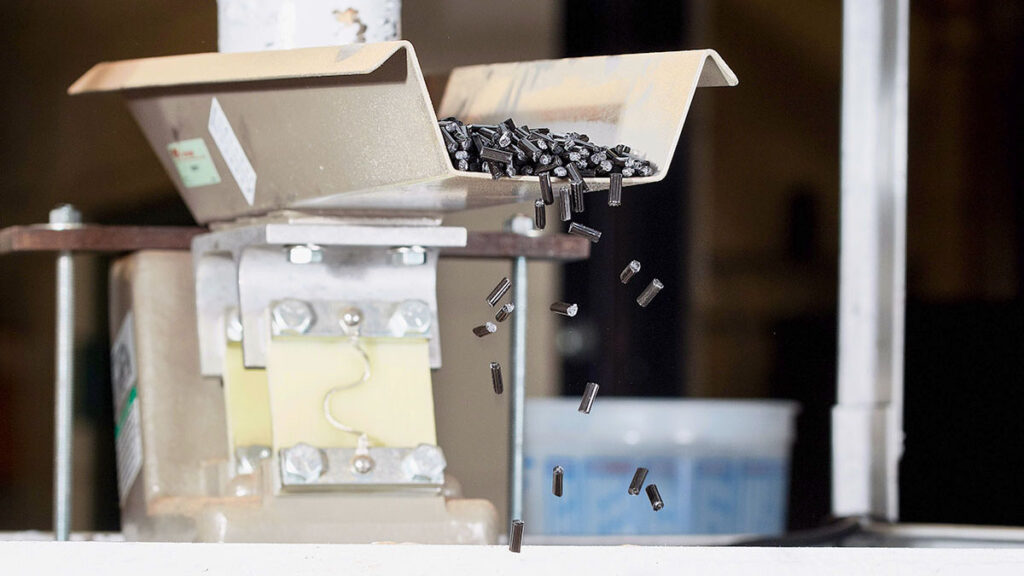

UT is helping train the next generation of innovators in casting and forging, which play a critical role in U.S. manufacturing. UT plans to host three free Metallurgical Engineering Trades Apprenticeships and Learning initiative – or METAL – bootcamps each year to address workforce needs.

Learn more about METAL bootcamps.

HAMMER Research Center

UT is a core member of The Hybrid Autonomous Manufacturing, Moving from Evolution to Revolution (HAMMER) Engineering Research Center, a multi-institutional research center focused on developing and deploying revolutionary intelligent autonomous manufacturing systems and educating a future manufacturing workforce.

Discover HAMMER.

Army Collaboration

UT researchers are working to improve materials and manufacturing methods that could significantly advance capabilities of the US Army Combat Capabilities Development Command (DEVCOM) Army Research Laboratory, including developing the next generation of vehicles, increasing the distance of its long-range arsenal, and exploring designs for vertical lift vehicles of the future.

Read about next-generation military equipment.

CNS Partners with UT

Consolidated Nuclear Security (CNS), which operates both Y-12, located in Oak Ridge, Tennessee, and the Pantex Plant in Amarillo, Texas, for the National Nuclear Security Administration, has a $9.5 million agreement allowing access to UT’s faculty, students, and research facilities to drive the implementation of new technologies for innovations applied to key national security mission areas.

Learn about UT’s contribution to nuclear security.

Our Researchers

-

Associate Professor, Mechanical, Aerospace & Biomedical Engineering

Developing new high-performance materials for additive manufacturing technologies, printable fiber-reinforced polymer and ceramic matrix composites, multi-material hybrid structures

-

Professor, Chemistry

Organic photovoltaics and conjugated polymers, nanocomposites and block copolymers, lignin and renewable polymers

-

Professor, Mechanical, Aerospace & Biomedical Engineering

Additive manufacturing of polymer and composite structures, new material development, melt flow characterization, optimizing process-structure-property relationships, tooling applications for large-scale additive manufacturing

-

Associate Professor, Mechanical, Aerospace & Biomedical Engineering

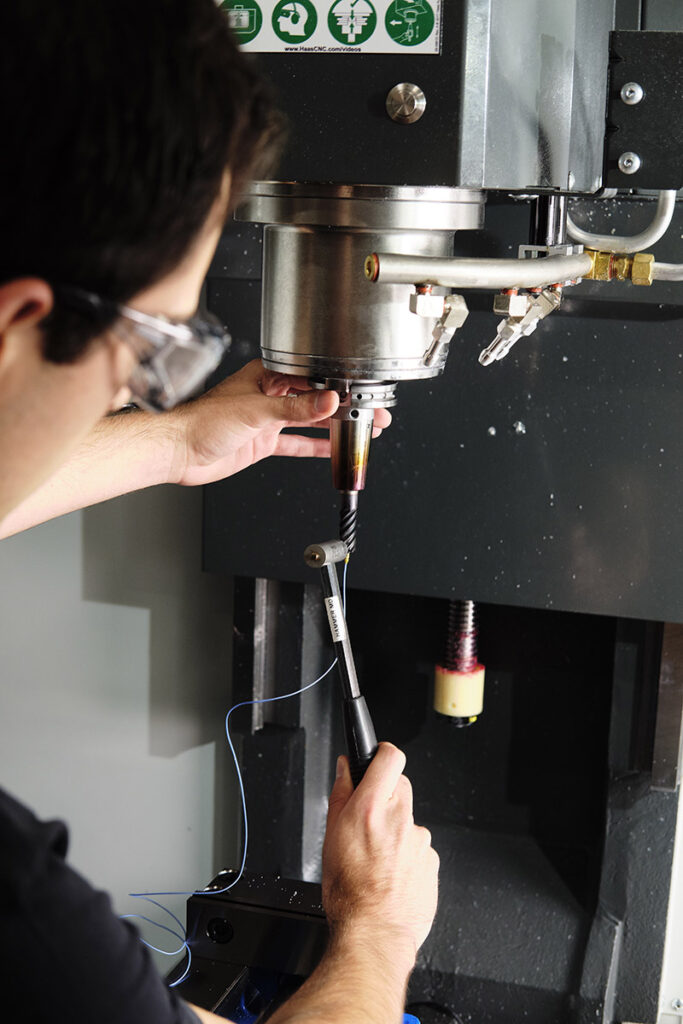

Additive manufacturing, precision engineering, design of precision electro-mechanical systems and mechanisms, machine learning for manufacturing processes, metrology processes, opto-mechanics and opto-electronics, design and process optimization, hierarchical material design, material process-structure- property relationships, meso manufacturing

-

Associate Professor, Industrial and Systems Engineering

Markov decision processes, dynamic programming, predictive analytics, reinforcement learning, time series analysis, anomaly detection, applied probability and statistics

-

Assistant Professor, Materials Science & Engineering

Phase transformations and microstructural evolution in metals and alloys, thermodynamic and kinetics, high-temperature materials, additive manufacturing

-

Peebles Professor, IAMM Chair of Excellence, Civil & Environmental Engineering

Carbon fiber reinforced polymeric composites and sandwich structures, environmental degradation, and multi-scale mechanics, multi-axial stress-strain-time behavior of multi-phase and granular materials, non-invasive characterization and residual stress using neutron and x-ray tomography and diffraction, direct numerical simulations and porous media

-

Associate Professor, Mechanical, Aerospace & Biomedical Engineering

Assembly, characterization, and application of biologically inspired and biomolecular material systems for engineered devices: biomimetic membranes for sensing, energy conversion, and actuation; uncovering membrane-nanomaterial interactions; soft, reconfigurable materials for neuromorphic computing

-

Assistant Professor, Industrial and Systems Engineering

Machine learning and data science for complex systems in science and engineering modeling; control and optimization of time, event and decision-driven complex systems; statistical methods, mathematical optimization, and scientific computation; manufacturing, operations engineering, system dynamics and cyber-physical systems

-

Professor, Chemical & Biomolecular Engineering

Self-assembly in polymeric systems, physics of confined polymers, thermodynamics of polymer blends, architectural design of polymers, lithographic materials, coatings, thin film membranes, x-ray scattering methods

-

UT-ORNL Governor’s Chair for Advanced Composites Manufacturing

Composites manufacturing, design and product development, concept to part, recycling and sustainable technologies, , hybrids, engineered plastics and high performance materials