Micro-Processing Research Facility

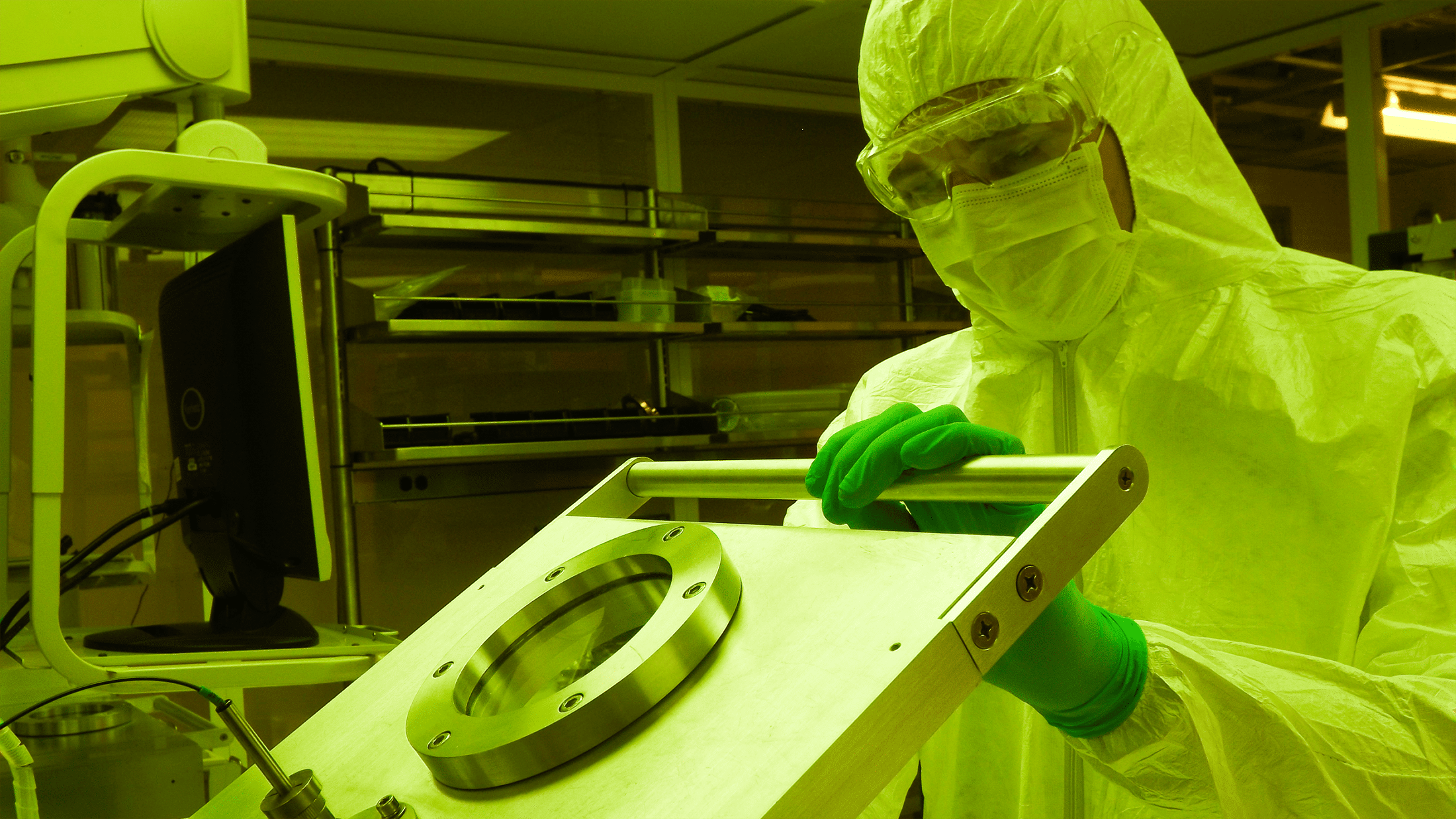

The Micro-Processing Research Facility (MPRF) is a state-of-the-art Class 100 cleanroom designed to support advanced research in microfabrication and semiconductor processing. Equipped with specialized tools for optical lithography, thin film deposition, plasma etching, and materials characterization, the facility enables high-precision device fabrication and breakthrough innovations in:

- Semiconductor and optoelectronic device manufacturing

- Microelectromechanical systems (MEMS) and microfluidics

- Quantum materials and superconducting circuits

- Biomedical microdevices and lab-on-a-chip technologies

As part of the Institute for Advanced Materials and Manufacturing (IAMM), MPRF fosters interdisciplinary collaboration, providing researchers with the resources necessary to push the boundaries of materials science, microelectronics, and emerging computing technologies.

Staff

Eric Lukosi, PhD

Facility Director

Professor and Charles P. Postelle Professor, Nuclear Engineering

421 Zeanah Engineering Complex

Knoxville, TN 37996-2300

865-974-6568

elukosi@utk.edu

Amine Benkechkache, PhD

Facility Manager

Research Scientist

nstitute for Advanced Materials and Manufacturing (IAMM), Rm, 213

Knoxville, TN 37920

865-221-4972

mbenkech@utk.edu

Facility and Environmental Control

MPRF provides an ultra-clean environment essential for nanofabrication and semiconductor processing. Key infrastructure includes:

- ISO Class 100 cleanroom environment with advanced HEPA filtration for particulate-free processing

- HF-rated fume hoods for wet chemical processing, etching, and hazardous material handling

- General-purpose fume hoods for solvent-based processes and photolithography applications

These environmental controls ensure high reproducibility, process stability, and contamination-free fabrication for research at the micro- and nanoscale.

Core Research Capabilities

Optical Lithography & Patterning

- Karl Suss MA6 Mask Aligner – A photolithography system supporting substrates up to 100 mm (4 inches). It features a broadband mercury lamp (i-line: 365 nm), multiple exposure modes, and split-field microscope alignment with Bottom-Side Alignment (BSA) capability, achieving micron-scale resolutions.

- Model 6808 Programmable Spin Coating System – A precision spin coater designed for uniform photoresist application on wafers up to 100 mm (4 inches), with fully programmable spin profiles ensuring repeatability and control.

Thin Film Deposition & Growth

- AJA International ATC Orion-5 Magnetron Sputtering & Thermal Evaporation System – A versatile deposition system supporting RF and DC sputtering for metals, dielectrics, and compound semiconductors. Includes a thermal evaporator for high-purity metal deposition and substrate heating up to 850 K.

- Plasmatherm Shuttelock SLR-730-PECVD System– A plasma-enhanced chemical vapor deposition (PECVD) system for depositing silicon-based films, including SiO₂, Si₃N₄, poly-Si, and graphene, ensuring conformal coatings with precise thickness control.

Plasma Etching & Microstructuring

- Unaxis Shuttelock SLR-760-RIE System– The capacitively coupled reactive ion etching is designed for anisotropic etching of silicon and other materials using fluorine chemistry. It also supports oxygen plasma etching for organic material removal and surface treatments.

Thermal Processing & Anealing

- MTI EQ-GSL-1500X-50 – A compact high-temperature tube furnace reaching 1550°C, featuring SiC rod heating elements for fast heating/cooling. Ideal for material synthesis, annealing, and sintering, it includes a vacuum sealing assembly for controlled atmospheres. A high-precision SCR digital controller ensures ±1°C accuracy with 51-segment programmability for precise temperature control.

- MTI OTF-1200X – A split-tube furnace for semiconductor annealing and materials research, operating up to 1200°C with controlled gas flow. It includes a KF25 gas outlet, digital vacuum gauge, and an OMEGA thermocouple for precise temperature monitoring. The split design allows easy sample handling, while its 30-segment controller ensures ±1°C accuracy for stable thermal processing.

General Processing & Sample Preparation

- Harrick Plasma Cleaner – A plasma surface treatment system for removing organic contaminants and enhancing adhesion for microfabrication processes.

- Novascan UV/Ozone Cleaner – A High-performance systems for atomic-level surface cleaning, resist stripping, wafer preparation, and chemical surface modification. Widely used in nanotechnology, semiconductor research, and material sciences for precision cleaning and surface treatment.

- Ultrasonic Cleaners – Used for precision cleaning of substrates, ensuring contamination-free processing.

- MTI Polishing Machine – Used for high-precision polishing of crystal components, semiconductor wafers, and ceramic substrates. It functions with fixtures for automated sample processing.

Surface Profiling & Metrology

- WYKO NT8000 Optical Profiling System – A white-light interferometry-based profiler for 3D surface measurements with sub-nanometer resolution, essential for characterizing step heights and roughness in microfabrication.

- Zeiss Axio Lab.A1 Microscope – A high-resolution optical microscope with 10X, 50X, and 100X objectives, supporting brightfield and darkfield imaging for material inspection and defect analysis.

Semiconductor Device Characterization

MPRF provides a comprehensive suite of electrical and materials characterization tools to support semiconductor and thin-film research:

- Four-Point Probe – Precise resistivity and conductivity measurements

- Hall Effect & Van der Pauw Measurements – Carrier concentration and mobility analysis

- Current-Voltage-Temperature (IVT) Measurements

- Capacitance-Voltage (CV) Measurements

These capabilities enable thorough evaluation of electronic, optoelectronic, and quantum devices, ensuring optimized performance and material properties.

Applications & Emerging Research Areas

MPRF supports cutting-edge research across multiple disciplines, enabling innovations in:

Semiconductor Devices & Nanoelectronics

- Advanced CMOS-compatible materials, 2D semiconductors, and flexible electronics

- Photonic integrated circuits (PICs) and quantum dot devices

- Spintronics and neuromorphic computing architectures

MEMS & Microfluidics

- MEMS-based actuators, sensors, and RF components

- BioMEMS for medical diagnostics and lab-on-a-chip systems

Quantum & Superconducting Devices

- Superconducting Josephson junctions for quantum qubits

- Novel materials for quantum computing and cryogenic electronics

Energy Harvesting & Advanced Materials

- Thin-film thermoelectrics and perovskite solar cells

- 2D materials for energy storage and supercapacitors

Through these diverse research areas, MPRF plays a critical role in shaping the future of electronics, photonics, and nanotechnology.

Collaboration & Industry Partnerships

MPRF is open to academic institutions, government laboratories, and industry partners seeking access to nanofabrication and characterization tools. Our facility provides:

- Expert consultation & process development support

- Access to advanced fabrication & characterization techniques

- Collaborations with leading semiconductor & materials science researchers

Key Collaborations & Funding Opportunities

MPRF actively collaborates with academic institutions, government agencies, and industry partners to advance research in microfabrication and materials science. The facility supports graduate students across multiple departments, contributing to research while fostering innovation through interdisciplinary projects. As the only open-access Class 100 cleanroom on campus, MPRF enables external collaborations that drive published research and technological advancements. Projects are supported through funding sources; such as NSF and DoE ensuring sustained contributions to next-generation semiconductor and quantum technologies.

Why Choose MPRF?

- World-Class Cleanroom Infrastructure – Class 100 processing space with HEPA filtration

- Comprehensive Fabrication Capabilities – Lithography, deposition, etching, and advanced characterization

- Interdisciplinary Research Hub – Supporting semiconductor, MEMS, and quantum research

- Industry & Academic Collaboration – Open to startups, universities, and government labs

Contact us today to schedule a tour or explore research opportunities!

User Rates

Listed rates below are per hour unless otherwise specified.

| Internal | Academic | Market | |

|---|---|---|---|

| Service 1: Unassisted Thin Film | $37 | $56 | $74 |

| Service 2: Advanced Assistance, including training | $117 | $177 | $234 |

| Service 3: Clean Room Access | $24 | $36 | $48 |

| Service 4: Noble Metal Gold | $14/100nm | $21/100nm | $28/100nm |

| Service 5: Noble Metal Platinum | $26/100nm | $39/100nm | $52/100nm |

| Service 6: Intermediate Assistance | $36 | $54 | $72 |

| Service 7: Basic Assistance | $19 | $29 | $38 |

User rates subject to change without notice.

Additional Resources

Existing users may book time via Stratocore. New users contact Amine Benkechkache. View the MPRF safety manual, forms, and equipment manuals.