Circular Bioeconomy

Prioritizing renewable resources and waste prevention

We envision a future in which nothing is wasted and the sustainability of carbon-friendly bio-based manufacturing replaces petroleum as a primary driver for a thriving economy.

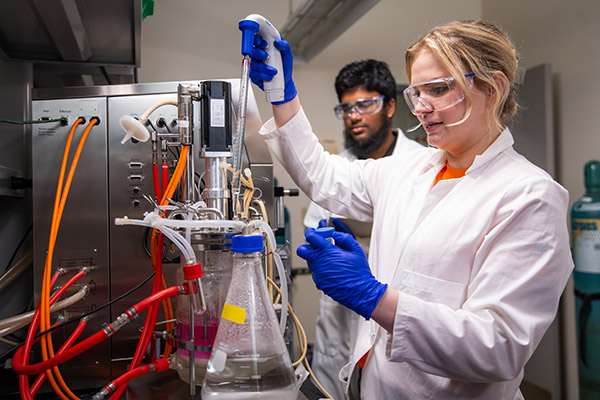

UT faculty and students are developing novel processes to make fuels, materials, and other bio-based products from renewable plant materials. This research is disrupting the predominant “take, make, waste” paradigm to deliver innovative solutions that reduce waste and greenhouse gas emissions while cultivating valuable new opportunities for US agriculture, forestry, and business.

UT’s Approach

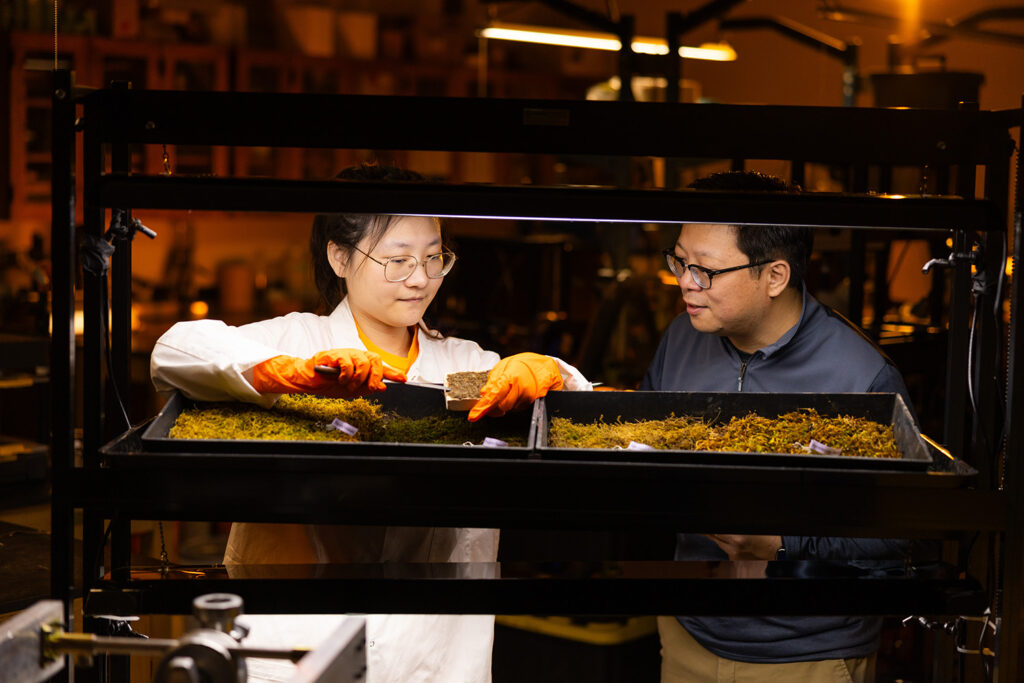

UT faculty seek to improve environmental sustainability, economic prosperity, and performance and integration of circular bioeconomy–based processes at each stage of the manufacturing supply chain. For example, faculty in the Center for Renewable Carbon work with industry partners to evaluate biochar—a byproduct of biofuel production—as a carbon-sequestering technology that aims to reduce the carbon intensity of advanced manufacturing processes.

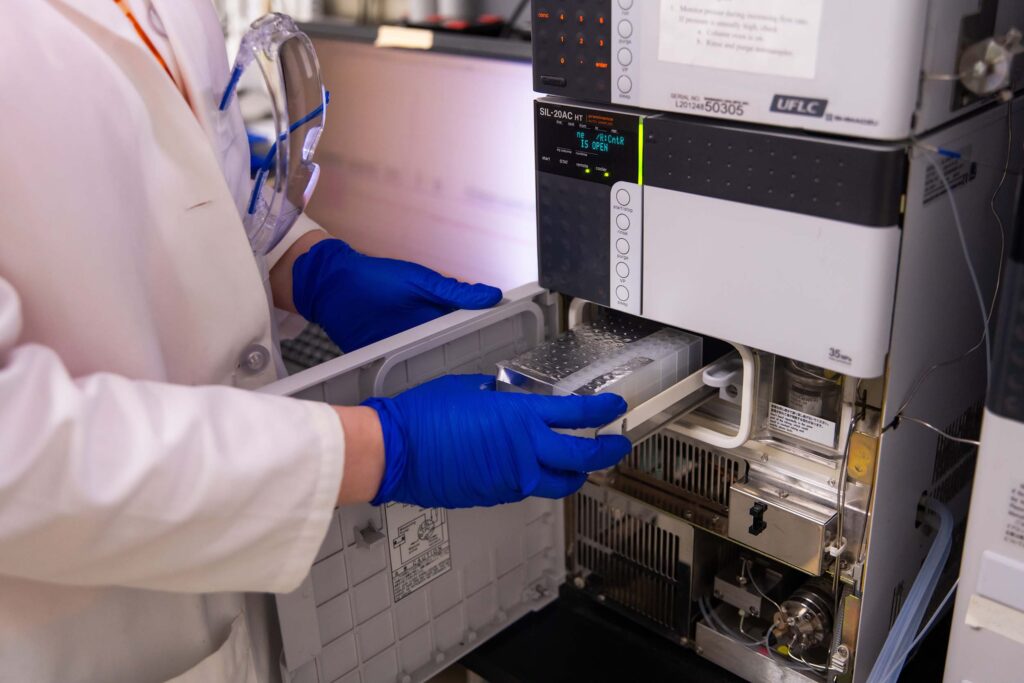

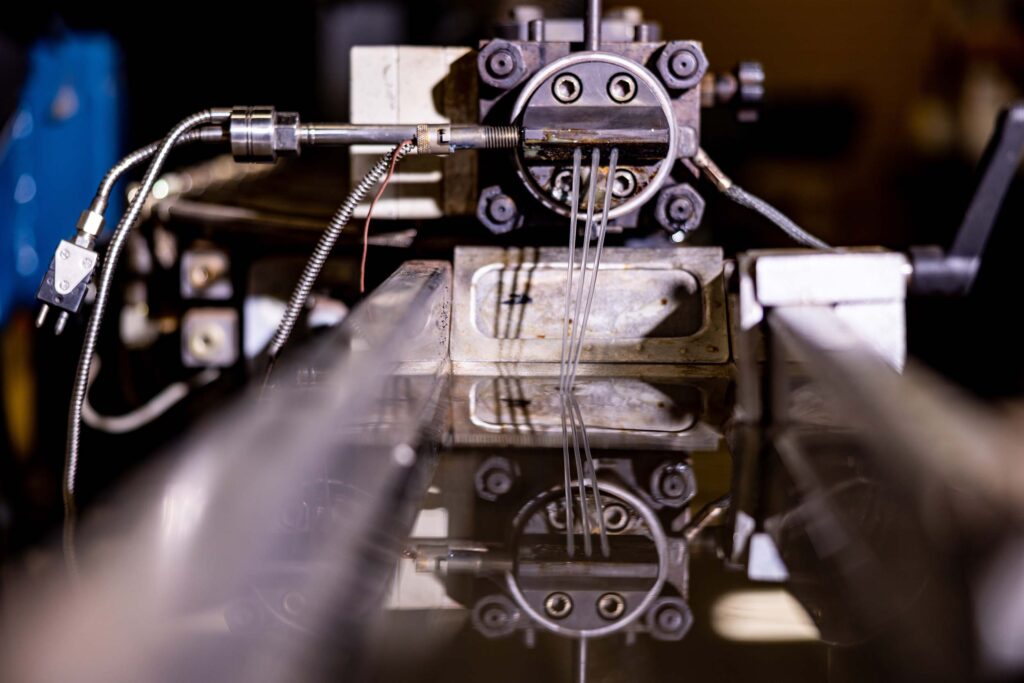

UT’s focus on biomass-to-value supply chain is also supporting our researchers in the discovery of the fundamental principles behind the conversion of plant matter using heat and biocatalysts. The ultimate goal of this pioneering research is realizing the potential of new biorefining processes to not only produce sustainable fuels but also generate new processes and technologies for high-value products such as those used in automotive manufacturing.

With a focus on sustainable manufacturing, research teams across the university are focused on the deployment of low-carbon biofuels and biobased materials, empowering a breadth of industries to reduce their fossil-based fuels and materials. In this area, UT faculty are developing and enhancing sustainable polymers, polymer composites, carbon fiber composites, and paper fiber composites derived from lignin and other plant components. As a next step in these technologies, UT is working to transform plant-derived lignin into nanostructured activated carbon for energy storage applications including supercapacitors.

Our partnerships with Oak Ridge National Laboratory are ensuring the delivery of new technologies for the bioeconomy of tomorrow. The UT–Oak Ridge Innovation Institute has committed $20 million to expand UT and ORNL’s robust circular bioeconomy research. Together we are working with Tennessee’s agriculture and automotive industries to improve biomass cultivation; develop cost-effective bioderived products designed to be repaired, reused, recycled, composted, and finally combusted for energy; and design metrics to quantify circular systems’ social, environmental, and economic value.

“When you combine UT’s strengths in this space, Tennessee’s mobility and biomass industries, and collaboration with ORNL, we are pushing the limits of science forward.”

—Nicole Labbé, Professor of Biomass Chemistry and Director of the Center for Renewable Carbon

Highlights

Our Researchers

-

Professor, Civil & Environmental Engineering

Renewable energy production, waste to energy processes, treatment and reuse of waste from energy industries, environmental impact of energy management practices

-

Professor & Assistant Director, Center for Renewable Carbon

Circular bioeconomy, integrated biorefining, sustainable advanced manufacturing, green chemistry, bioenergy, bioderived chemicals and materials

-

UT–ORNL Governor’s Chair for Polymer Science

Solid state batteries, flow batteries, fundamentals of ion and proton transport in liquids and polymers, ion transport at interfaces, polymer dynamics, glass transition

-

Associate Professor, Civil & Environmental Engineering

Sustainable infrastructure materials, decarbonization, building energy, autonomous construction

-

Professor, Biosystems Engineering & Soil Science

FEWSUS (food-energy-water nexus), fate, transport and bioavailability of contaminants in the environment, physical foundation of soil microbial processes, soil carbon, soil hydrology, plant-soil water relation modeling