Advanced Materials

Solving tomorrow’s technological challenges through the discovery of novel materials and manipulating properties to make promising materials stronger and smarter

The development of advanced materials is rarely the unexpected discovery of a diamond in the rough. More commonly, it results from intentionally manipulating a material’s composition and processing parameters to achieve the desired structure at the appropriate scale to produce the desired performance.

Given that the parameter space for advanced material exploration is infinite, successful endeavors require a clear understanding of foundational principles that span several disciplines, including chemistry, physics, and various engineering fields. Entrepreneurship and innovation are necessary to translate fundamental research to applied technologies.

Our Approach To Innovation

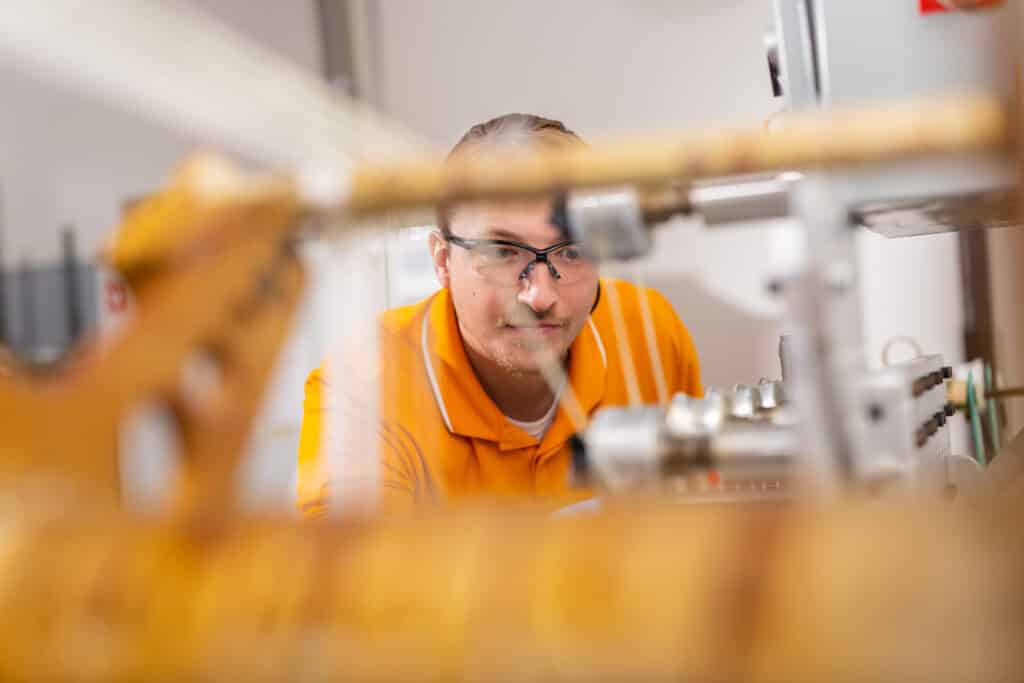

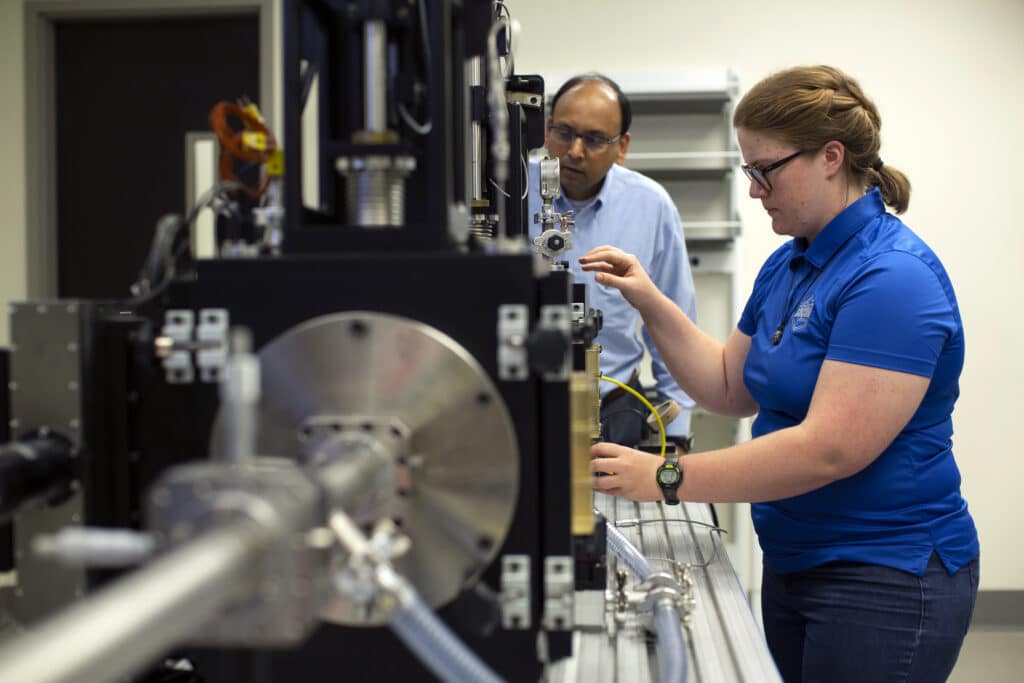

Advanced Materials research at UT begins with multi-disciplinary teams collaborating to identify opportunities for advanced material development. A highly integrated experimental and multiscale modeling/simulation approach is employed to engineer a broad range of materials with a desired micro- or nano-structure.

Specific areas of interest include dynamics of complex fluids, such as polymeric and biological fluids, fiber suspensions, interfacial properties, and colloidal systems as well as the synthesis of functional nanoparticles and thin films.

Additionally, UT is highly focused on the development and prototyping of advanced fiber reinforced plastics and composites. Core competencies are in product and process development, characterization, modeling and simulation, and the nondestructive evaluation of advanced thermoset and thermoplastic composites.

Highlights

Recycling Wind Turbine Blades

UT is developing a new technology for the large-scale recycling of wind turbine blades into new recycled composites. This technology recovers the glass fiber from reinforced polymer composites and allows the recycled fiber to be reused in new composite applications such as vehicle lightweighting, other renewable energy systems components, and performance sports equipment.

FRP Composite Bridge

UT researchers and engineering students worked with industry partners to develop and install a new high-tech bridge in north central Tennessee, equipped with a fiber-reinforced polymer (FRP) composite material bridge deck embedded with fiber optic sensors to monitor and provide critical performance and safety data.

Lighter Liftgate for Volkswagen

UT researchers collaborated with Volkswagen engineers to design and manufacture a liftgate made of a novel composite for the Volkswagen Atlas, which reduces weight by 35 percent and lowers the company’s investment cost.

Finding Flaws in Rubber

UT researchers partnered with Eastman Chemical Company to develop a new method to ensure consistency and quality in rubber manufacturing which is likely to show real-world impact on material sustainability and durability for products such as car tires.

Talent

-

Associate Dean for Research, Professor, College of Veterinary Medicine

Biochemistry and cell biology, animal production, veterinary sciences, biomedical engineering, biomaterials, chemical engineering, food sciences, materials engineering, regenerative medicine, clinical sciences, pharmacology and pharmaceutical sciences

-

UT-ORNL Governor’s Chair for Advanced Manufacturing

Computational materials science, fundamental issues in non–equilibrium phase transformations, application of in-situ neutron and synchrotron diffraction tools, laser surfacing for improvement of structural and biomaterial surfaces, novel phase transformation concepts to join nanostructured materials

-

Associate Professor, Mechanical, Aerospace & Biomedical Engineering

Developing new high-performance materials for additive manufacturing technologies, printable fiber-reinforced polymer and ceramic matrix composites, multi-material hybrid structures

-

Professor, Chemistry

Organic photovoltaics and conjugated polymers, nanocomposites and block copolymers, lignin and renewable polymers

-

Research Professor, Large Animal Clinical Sciences

Advancing regenerative medicine, tissue engineering, cell-based therapies for treatment of disease

-

Professor, Mechanical, Aerospace & Biomedical Engineering

Additive manufacturing of polymer and composite structures, new material development, melt flow characterization, optimizing process-structure-property relationships, tooling applications for large-scale additive manufacturing

-

Associate Professor, Mechanical, Aerospace & Biomedical Engineering

Additive manufacturing, precision engineering, design of precision electro-mechanical systems and mechanisms, machine learning for manufacturing processes, metrology processes, opto-mechanics and opto-electronics, design and process optimization, hierarchical material design, material process-structure- property relationships, meso manufacturing

-

Professor, Materials Science & Engineering

Mechanical behavior, fatigue and fracture behavior, nondestructive-evaluation, and neutron/synchrotron studies of advanced materials, including bulk-metallic glasses, nano-structural materials, high-entropy alloys, superalloys, steels, and intermetallics.

-

Assistant Professor, Materials Science & Engineering

New insights into complex functional materials, both bulk and nano, through advances in structural characterization, ferroelectric oxides, energy conversion materials, nanoscale catalysts

-

Peebles Professor, IAMM Chair of Excellence, Civil & Environmental Engineering

Carbon fiber reinforced polymeric composites and sandwich structures, environmental degradation, and multi-scale mechanics, multi-axial stress-strain-time behavior of multi-phase and granular materials, non-invasive characterization and residual stress using neutron and x-ray tomography and diffraction, direct numerical simulations and porous media

-

Professor, Materials Science & Engineering

Materials engineering, macromolecular and materials chemistry, atomic/molecular physics, inorganic chemistry, neutron and X-Ray powder diffraction, small molecule crystallography, ceramic synthesis, structure/property relations

-

Professor, Mechanical, Aerospace & Biomedical Engineering

Manufacturing, machining, vibrations, measurement, uncertainty analysis

-

UT-ORNL Governor’s Chair for Advanced Composites Manufacturing

Composites manufacturing, design and product development, concept to part, recycling and sustainable technologies, , hybrids, engineered plastics and high performance materials