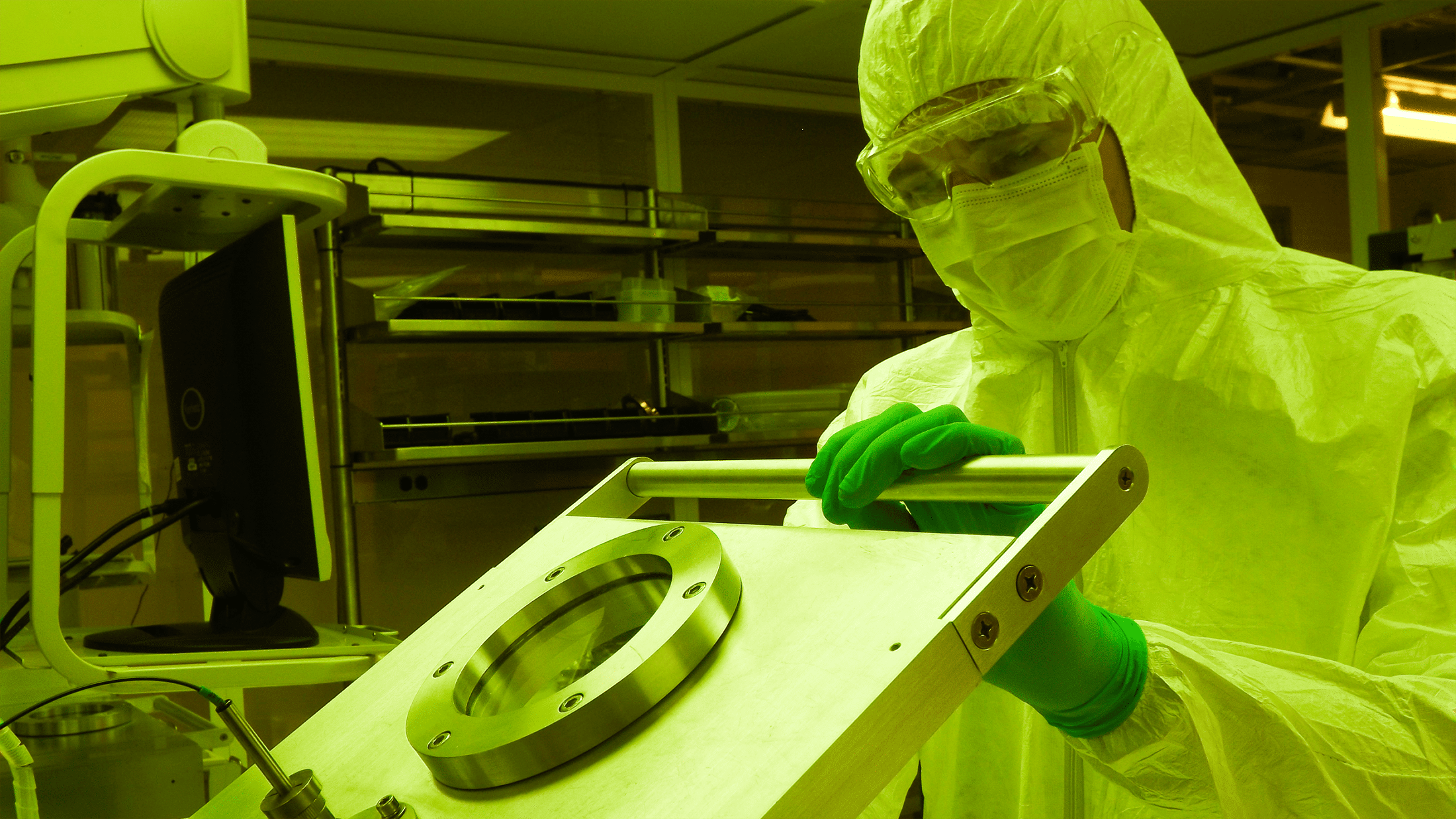

Micro-Processing Research Facility

The Micro-Processing Research Facility (MPRF) provides researchers the ability to conduct micro-processing fabrication processes. Services include optical lithography, thin film deposition, capacitively coupled reactive ion etching, and silicon-based plasma enhanced chemical vapor deposition processes. This equipment is housed in a class 100 clean room with all necessary facilities and supporting process equipment.

In combination with other IAMM facilities, MPRF provides researchers with the means to conduct cutting-edge investigations in materials science and engineering.

Staff

Eric Lukosi

Director

MPRF@utk.edu

865-974-6568

Instruments

AJA Magnetron Sputtering System

The AJA International ATC Orion-5 confocal magnetron sputtering system has the ability to sputter thin films of both dielectrics and metals. Three materials can be deposited in one process using either DC or RF biasing. RF substrate biasing is available along with substrate heating up to 850 °K.

Karl Suss Contact Printer

The Karl Suss MA6 optical lithography system is configured to process four inch or smaller wafers. The system utilizes a mercury lamp but is ideal for I-line resist processes. This system can be used for both positive and negative patterning processes in-combination with other equipment within MPRF to create advanced structures as required by the user.

Plasmatherm PECVD

The Plasmatherm Shuttelock SLR-730-PECVD system is equipped to grow poly-silicon, silicon oxide, silicon nitride, and silicon oxide. The system is also capable of growing other carbon-containing films such as graphene.

Unaxis RIE

The Unaxis Shuttelock SLR-760-RIE system is designed to etch various forms of silicon containing compounds using fluorine chemistry. Further, oxygen-based etching processes are also available. The system can process up to eight-inch wafers.

General Equipment

MPRF has various items to support users in various processes, including a 1500°C GSL-1500X-50-UL tube furnace, SCS 6800 spin coater, Harrick Plasma PDC-001 oxygen plasma cleaner, Kulicke & Soffa 4523D wedge bonder, 5 inch tube furnace, UV/Ozone, and polishing machine. Other sample processing equipment is available in supporting IAMM facilities.

User Rates

Listed rates below are per hour unless otherwise specified.

| Internal Academic | External Academic | Commercial | |

|---|---|---|---|

| Unassisted Thin Film | $53 | $82 | $108 |

| Advanced Assistance, including training | $105 | $159 | $210 |

| Clean Room Access | $21.75 | $31 | $41 |

| Noble Metal Gold | $11/100nm | $15.13/100nm | $15.13/100nm |

| Noble Metal Platinum | $12/100nm | $16.80/100nm | $16.80/100nm |

| Intermediate Assistance | $47 | $71.17 | $94 |

| Basic Assistance | $16.20 | $24.53 | $32.40 |

User rates subject to change without notice.

Additional Resources

Existing users may book time via Stratocore. New users contact Eric Lukosi. View the MPRF safety manual, forms, and equipment manuals.