January 2023 marks three years since the Volkswagen North American Innovation Hub, located at the UT Research Park at Cherokee Farm, launched with a Tennessee Orange liftgate.

The hub established a new collaboration between University of Tennessee, Knoxville, faculty and students, Oak Ridge National Laboratory scientists, and Volkswagen engineers—a collaboration that continues to thrive with a variety of projects.

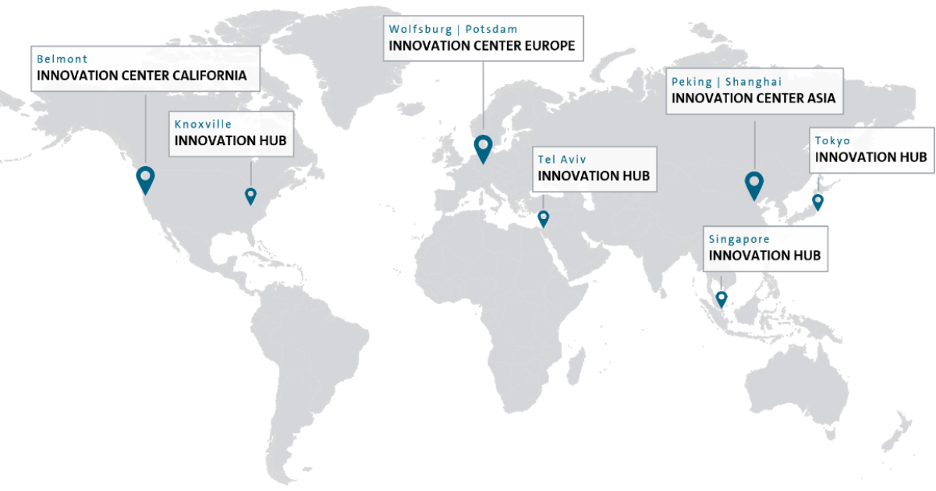

“The global Volkswagen Group aims to build a more sustainable vision of future mobility worldwide, and we connect the best researchers in the world to make that a reality,” said Nikolai Ardey, executive director of Volkswagen Group Innovation. “Co-innovating with partners like Oak Ridge National Laboratory and the University of Tennessee helps to multiply the power of Volkswagen’s international innovation team.”

The hub is home to some of the most innovative automotive research being conducted anywhere in the world. Researchers are developing composites for car body parts that are lighter yet stronger and plant-based materials for interior designs; advancing vehicle electrification, including new wireless charging concepts; and creating upcycling concepts and processes for materials conventionally deemed nonrecyclable, such as fiber-reinforced composites.

The hub is an exemplar of UT’s innovative research model and the kind of partnerships the university pursues—those that holistically align the efforts of academia, industry, and government to tackle complex challenges through place-based innovation.

“Volkswagen is a model partner and understands the value that co-location with a world-class research university creates,” said UT Vice Chancellor for Research and Innovation Deb Crawford. “Together we are identifying technological solutions that could lead to a more sustainable future for our planet.”

Central to the hub’s success is a thoughtful and dedicated long-term approach. The journey of Marton Kardos, a student turned research scientist for Volkswagen, exemplifies the power of what investing in students can do to develop and retain up-and-coming talent to ensure that the partnership thrives.

From International Research Student to Industry Expert

Kardos has lived in Knoxville since early 2020, but his story begins in Hungary.

While growing up in Budapest, he had an interest in cars that drove him to study engineering at the Budapest University of Technology and Economics. As a junior in mechanical engineering, Kardos attended a lecture given by a representative of Audi Hungaria, part of the Volkswagen Group and home to the world’s largest engine factory.

“I actually saved the poster of it,” said Kardos. “The title was ‘Materials in Car Manufacturing,’ and I thought, ‘This is what I want, exactly.’”

While working on his master’s degree in materials science at Hof University of Applied Sciences, he applied to Volkswagen, which he considered a long shot. He got a call saying that although the job he had applied for was taken, they had a better fit for him—a position at Volkswagen’s global headquarters in Wolfsburg, Germany, where he then had the opportunity from Volkswagen to pursue a PhD at Technical University Dresden.

As part of his PhD program Kardos spent the 2017–18 academic year at UT, where he met UT–ORNL Governor’s Chair Uday Vaidya and Peebles Professor Dayakar Penumadu, both faculty members in UT’s Tickle College of Engineering.

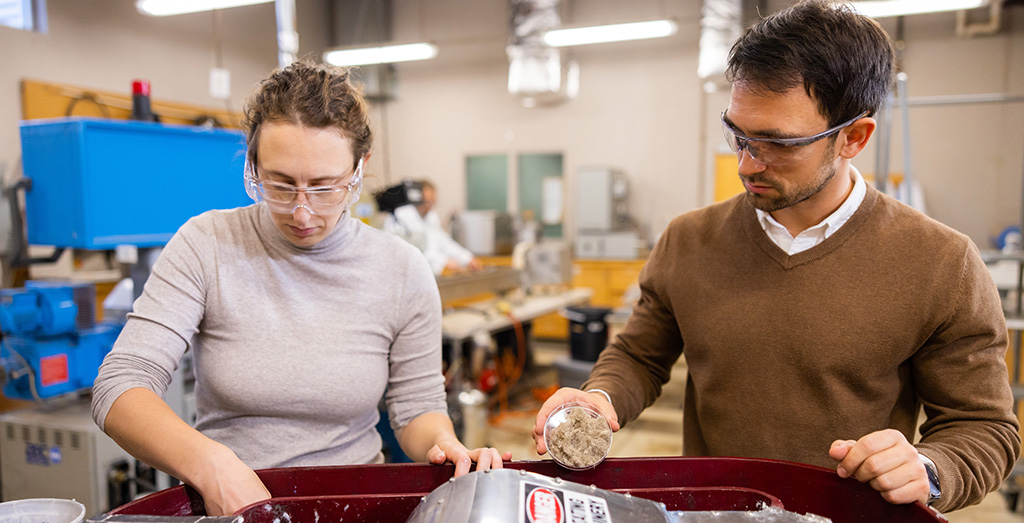

“I was working with a very specific type of material for which there was a lot of expertise at UT and Oak Ridge,” said Kardos. “Dr. Vaidya’s group actually had a sheet molding compound line. There was a flagship project being done by Hendrik Mainka, who back then was in Chattanooga at the Engineering and Planning Center of Volkswagen. Since this was the same material I was working on, it was a good fit to come over to UT and work with Dr. Vaidya and Dr. Penumadu on the material science part of things.”

Kardos worked specifically on projects defined by Volkswagen for his dissertation. He then returned to Germany to finish his research.

“I’ve always viewed the relationship as an exchange opportunity for UT students, through the Volkswagen PhD Fellows Program, to have the opportunity to train in Germany, and conversely, students from Germany like Marton have the opportunity to work in Knoxville,” said Marc Gibson, UT’s associate vice chancellor for research.

As part of the UT–Volkswagen partnership, the car manufacturer awarded fellowships to four other UT doctoral students—Andrew Foote in the Min H. Kao Department of Electrical Engineering and Computer Science, William Henken and Joey Michaud in the Department of Civil and Environmental Engineering, and Cecile Grubb in the UT Institute of Agriculture—to support programs of study similar to Kardos’s.

Cecile Grubb and Marton Kardos create a slurry from natural fibers in a lab at the Center for Renewable Carbon.

When Kardos expressed his desire to come back to the US, he was told that the VW Knoxville Hub was in the works. It was a natural fit.

In early 2022, Kardos defended his dissertation and completed his PhD from a conference room on the second floor of Innovation North at the UT Research Park. The defense began at 5 a.m. in order to accommodate a committee spread over three continents, with professors in Germany and China in addition to those at UT. It seems fitting that Kardos, a native Hungarian, holds the distinction of being the first PhD graduate to come from this international partnership between UT, Technical University Dresden, and Volkswagen.

Kardos is now working full time for Volkswagen with a focus on combining natural fiber-reinforced composites with recyclability of materials.

“I want to make sure that the carbon footprint of our cars can be lowered as soon as possible. Personally, it’s really important for me that I get to work for an industrial company while I’m on a campus. And I can enjoy not just a lab space and expertise of the University of Tennessee but also the academic surrounding. It’s really stimulating, and it’s just great to be around students and professors, and there’s so much research going on. There’s really no better workspace as a scientist.”

On the Front Lines of Industry Innovation

For companies such as Volkswagen, UT’s approach to partnerships provides excellent opportunities with mutual benefits. There is access to a network of faculty, leaders, students, and existing external partnerships as well as the ability to co-locate in proximity to other companies and agencies interested in similar research.

For UT and the East Tennessee region, partnerships not only put faculty on the front lines of industry innovation but also provide excellent opportunities to expose students to industry culture, making them attractive candidates in a competitive job market. The surrounding community benefits by having a workforce capable of responding to today’s most pressing challenges and creating technology that improves lives.

Volkswagen Group of America has been a valued partner of UT since opening its Chattanooga Assembly plant in 2011. The facility assembles the Volkswagen Passat all-electric ID.4 SUV and Atlas and Atlas Cross Sport SUVs specifically designed for the North American market. In 2019, Volkswagen broke ground to expand its footprint with a new electric vehicle production facility, which includes a 564,000-square-foot body shop addition and up to a thousand new jobs in Tennessee.

Volkswagen is one of the 130-plus members of IACMI: The Composites Institute, a community of industry partners, universities, national laboratories, and government agencies working to accelerate advanced composites development. IACMI is supported by the US Department of Energy and managed by a not-for-profit organization established by the UT Research Foundation.

A team of undergraduate and graduate students and researchers led by Vaidya created a novel composite liftgate for the VW Atlas that reduces weight by 35 percent, with lower investment costs and an improved environmental footprint compared to a conventional part. Researchers from ORNL, Purdue University, and Michigan State University were integral collaborators on the effort.